CusTomized ConnecTors.

Customized Connectors

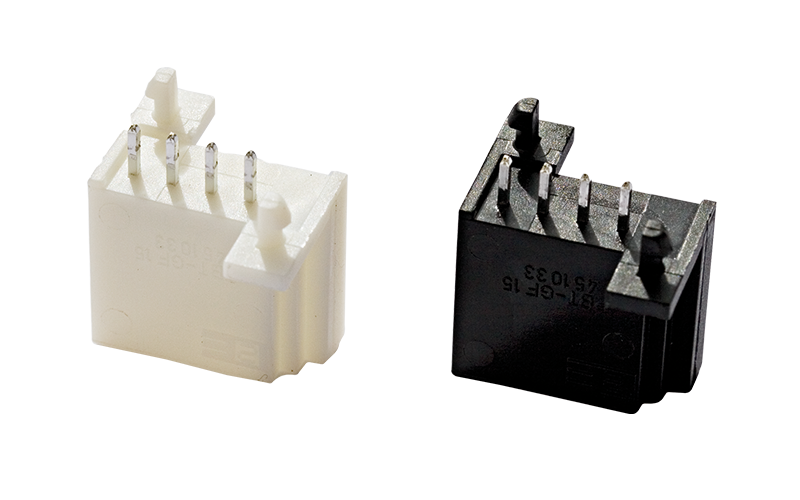

individual connectors- to meet customers’ requirements.

Numerous products can be produced in as wide a range as DIN connectors. In other cases it could, however, make sense to deviate from the norm. With our experience in development and construction of prototypes through to mass production we are the right partner.

E-Mail: info@2e-mechatronic.de Phone: +49 (0)7021 / 93010

Due to its individual design, the connector makes incorrect

wiring or the use of incompatible connection devices impossible.

Combination of several connectors and mechanical holding fixtures in the high temperature range of an assembly.

InTeresTing facTs

Creating your own connectors - reasons for new developments and their benefits

Standardized connectors cover many areas of application, but by no means all of them. The standard range of connectors may not provide a solution if, for example, a connector with an unusual number of contacts or for the transmission a very high current, is needed. Also the combination of different connectors, such as signal and high-current contacts, fluidic and optical connectors may require customization. The same applies to unusual spatial conditions which make the development of customized connectors in special shapes necessary. Another reason for the new development is the uniqueness of the of the entire product. A mix-up of assemblies (e.g. cable harnesses) is made impossible with connectors which are specifically designed for this product.